In the 1990s, molecular gastronomy began to emerge. Pioneers such as Spanish chef Ferran Adrià and British chef Heston Blumenthal started to introduce scientific instruments into the kitchen. Chefs discovered that liquid nitrogen could achieve effects that traditional cooking could not: instant freezing (such as making "smoky ice cream"), altering the texture of food (such as directly solidifying liquids into a crispy outer layer), and creating dramatic visual effects (the white smoke produced during vaporization). Heston Blumenthal introduced liquid nitrogen ice cream at his restaurant, The Fat Duck, which became a signature dish. This innovation not only changed the way traditional cooking was done, but also laid the foundation for the application of liquid nitrogen in ice cream manufacturing.

How Does Liquid Nitrogen Freezing Work?

The unique texture and visual effects of liquid nitrogen ice cream are primarily due to its core principle:

Ultra-low Temperature Flash Freezing: When liquid nitrogen comes into contact with the ice cream ingredients, it rapidly vaporizes and absorbs heat, freezing the mixture within seconds to tens of seconds. The resulting ice crystals are extremely small, avoiding the formation of large ice crystals that occur in traditional freezing processes. This results in a smoother and more delicate texture.

Locking in Flavor and Nutrition: Rapid freezing minimizes water loss and oxidation, preserving the natural aroma and freshness of the ingredients (especially suitable for flavor-sensitive ingredients such as fruits and nuts).

Why Liquid Nitrogen Ice Cream Is Smoother, Faster, and Cleaner

Smooth Texture without Ice Crystals: Ultra-rapid freezing forms microscopic ice crystals that are nearly imperceptible, delivering a silky-smooth mouthfeel.

On-Demand Preparation: No pre-frozen equipment required, enabling fresh ice cream production directly at point-of-sale (ideal for restaurants and dessert shops).

Healthier and Additive-Free: Rapid freezing reduces reliance on stabilizers and emulsifiers, supporting natural and clean-label formulations.

Unlimited Creativity: Flexible recipe adjustments allow incorporation of alcohol, liquid ingredients (e.g., uncaramelized syrup), and other components challenging for traditional methods.

Traditional vs. Liquid Nitrogen Methods

To better understand the uniqueness of liquid nitrogen ice cream, we can compare it with traditional ice cream making:

Comparison Item | Liquid Nitrogen Ice Cream | Liquid Nitrogen Ice Cream |

Freezing Time | A few seconds to tens of seconds | Several hours to a day |

Ice Crystal Size | Micron-level, no graininess | Larger, may produce ice crystals |

Texture | Lighter and smoother | Relatively dense |

Additive Requirements | Can be completely additive-free | Often requires stabilizers and emulsifiers |

Equipment Cost | Higher (requires liquid nitrogen tank, protective gear) | Lower (conventional ice cream machine) |

Applicable Scenarios | Instant making, high-end customization | Mass production, regular sales |

Where Is It Used? From Fine Dining to Science Shows

High-end Restaurants and Dessert Shops: Utilize the "smoke effect" of liquid nitrogen to attract customers and enhance the dining experience (e.g., molecular gastronomy restaurants).

Customization Services: Adjust sweetness and ingredients on-site according to customer preferences to achieve personalized production.

Events and Educational Demonstrations: Used in science popularization activities or interactive experiences for children to showcase the fascinating effects of low-temperature science.

Safety Precautions When Using Liquid Nitrogen

Prevent Frostbite: Operators must wear heat-insulating gloves and goggles to avoid direct contact of liquid nitrogen with the skin.

Ventilation: When liquid nitrogen vaporizes, it may displace oxygen. Operations should be conducted in well-ventilated areas to prevent the risk of suffocation.

Container Selection: Use containers that are resistant to low temperatures (such as stainless steel) to avoid the risk of shattering in ordinary glass or plastic due to low-temperature brittleness.

Liquid nitrogen tanks are not only a technological innovation in ice cream making, but also a key tool for enhancing product value and consumer experience. Looking ahead, with the growing demand of consumers for healthy food and unique experiences, liquid nitrogen ice cream is expected to find applications in more fields. From high-end catering to mass markets, from customized services to science popularization and education, liquid nitrogen ice cream represents not only a new culinary technique, but also the food industry's continuous pursuit of innovation and quality. As the technology becomes more widespread and costs decrease, liquid nitrogen ice cream may no longer be exclusive to high-end restaurants, but will enter the daily lives of more consumers, becoming an indispensable part of food culture.

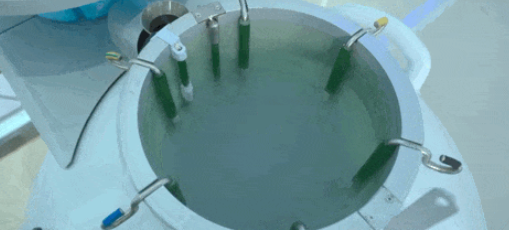

Why Etallwit Liquid Nitrogen Tanks Are Ideal?

The unique charm of liquid nitrogen ice cream is inseparable from the precise support of high-quality liquid nitrogen tanks. As a professional supplier of liquid nitrogen tanks, Etallwit is committed to providing you with safe, efficient, and reliable solutions for the storage and transportation of liquid nitrogen. Whether you are a practitioner in the high-end catering industry or an innovator passionate about making liquid nitrogen ice cream, Etallwit liquid nitrogen tanks can meet your needs.

Ready to bring innovation to your culinary or laboratory operations?

Contact our team for tailored solutions and expert advice.

Email: service@etallwit.com