Equipped with an intelligent touchscreen, stainless steel interior, forced convection design, and excellent temperature uniformity, our forced air drying oven is the ideal choice for drying and disinfection in laboratory settings.

Overview of Uses:

The forced air drying oven is designed specifically for laboratory environments, offering a reliable solution for sample drying, disinfection, and heating treatments. Thanks to its precise temperature control and efficient airflow circulation system, it provides a stable and dependable solution for experiments across various fields, including chemical research, material studies, and biological sample processing.

Working Principle:

Using a forced convection system, a high-power fan circulates the air to ensure uniform temperature distribution inside the oven. The unique vent adjustment technology allows users to control the ventilation rate based on their needs, ensuring effective drying while minimizing heat loss.

Structure:

The oven consists of several components, including:

· Chamber

· Heating system

· Electrical control system

· Air circulation system

· Safety protection system

Key Features:

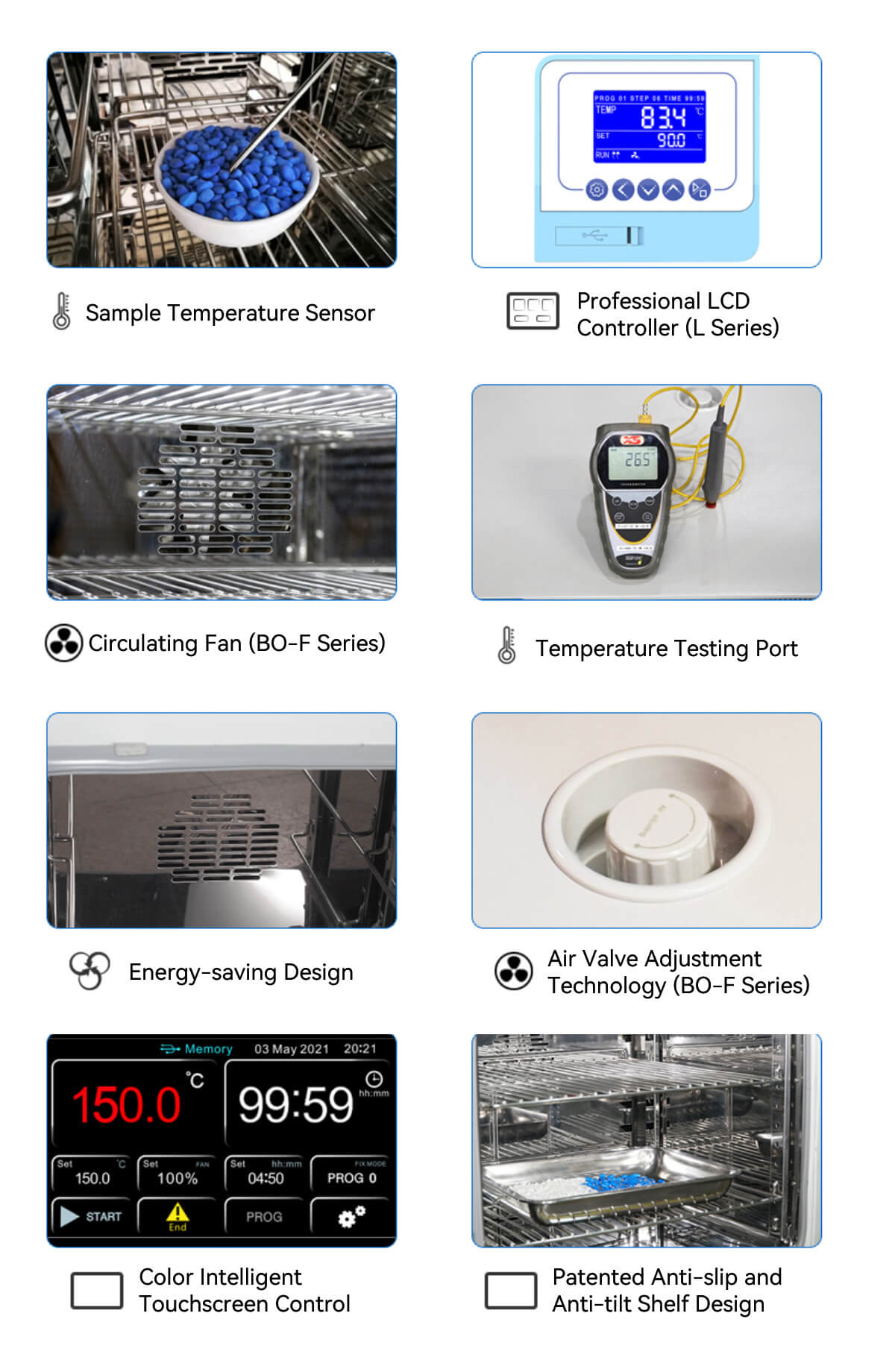

Smart Control:

· Built-in temperature sensors for real-time monitoring of sample temperature, ensuring precise drying.

· Supports timed and scheduled functions, minimizing wait time.

Energy-Saving Design:

· Synthetic silicone seals reduce heat loss by 25%, extending the device's lifespan.

Safety Assurance:

· Equipped with a dual temperature limit alarm, overcurrent protection, and thermal insulation design for comprehensive safety.

User-Friendly Design:

· Adjustable shelves cater to diverse experimental needs, and the oven can be stacked for space-saving purposes.

Data Support:

· Features a USB interface for temperature logging, and RS232 support for remote control.

Core Parameters & Optional Features:

· Instrument Type: Precision Oven

· Temperature Range: Amb +10°C to 200°C (up to 300°C)

· Temperature Uniformity: ±2.0°C (at 100°C)

· Temperature Resolution: 0.1°C

· Heating Time (Room Temp to 100°C): 25 minutes

· Interior Material: 304 Stainless Steel

· Heating Method: Forced Air Circulation

Optional Configurations:

· Sample temperature sensor for real-time monitoring of sample temperature.

· RS232 data interface for remote control via software.

· Glass inner door design for easier observation of samples.

· Integrated control system for automatic drying.

Usage Precautions:

1. Ensure all connections are secure to prevent malfunction during operation.

2. Regularly calibrate temperature sensors to ensure accuracy.

3. Adjust temperature settings based on sample requirements to prevent sample damage.

4. Minimize the number of times the door is opened to maintain temperature uniformity and improve drying efficiency.

5. Clean the interior after each use and regularly inspect seals and heating components for wear.

6. Place the unit in a dry, ventilated area to avoid humidity or high-temperature impacts on performance.

About Us:

Etallwit Scientific specializes in the development and sale of high-quality laboratory equipment and solutions. We are committed to providing reliable and superior laboratory equipment for researchers globally. Our forced air drying ovens comply with international safety standards and incorporate multiple safety.

Ready to enhance your laboratory efficiency with our advanced forced air drying oven? Contact us today to get a detailed consultation or request a quote. Don't forget to subscribe to our newsletter for the latest updates on laboratory equipment and exclusive offers. Let Etallwit Scientific be your trusted partner in achieving groundbreaking research results!