A dry bath incubator is a laboratory device used to maintain a constant temperature during an experiment. It is a highly accurate and stable temperature control device that provides accurate temperature control and rapid temperature change.

The main components of a dry bath incubator include heaters, coolers, temperature sensors and control units. The heater is used to provide heat to maintain a constant temperature; the cooler is used to rapidly cool down the temperature when it needs to be lowered; the temperature sensor is used to monitor the current temperature and transmit this information to the control unit; and the control unit controls the operation of the heater and the cooler based on the difference between a preset temperature value and the current temperature value to maintain a constant temperature.

In experiments,dry bath incubators can be used in a wide range of different experimental scenarios. For example, in a biology lab, adry bath incubator can be used to maintain a constant temperature in cell cultures to ensure proper cell growth and division. In chemistry labs,dry bath incubators can be used to control the temperature of chemical reactions to ensure accuracy and reproducibility.

Another use case is protein crystallography research. In this field, dry bath incubators can be used to maintain a constant temperature during protein crystallization to ensure that proteins are crystallized under the correct conditions and that accurate structural analysis can be performed.

In addition,dry bath incubators can be used in genomics and bioinformatics research. For example, in gene sequencing experiments,dry bath incubators can be used to maintain the temperature of a PCR instrument to ensure that gene fragments can be amplified and detected under the correct conditions.

In conclusion, a dry bath incubator is a very important piece of laboratory equipment that can provide accurate temperature control and rapid temperature changes for a variety of different experiments. The proper use of dry bath incubators in experiments can help researchers obtain more accurate and reliable results.

What is a dry bath incubator? Application cases in the experiment

2025-4-25

How important are freezing racks in liquid nitrogen tanks?

Fully Autoclavable Mechanical Pipette

popular article

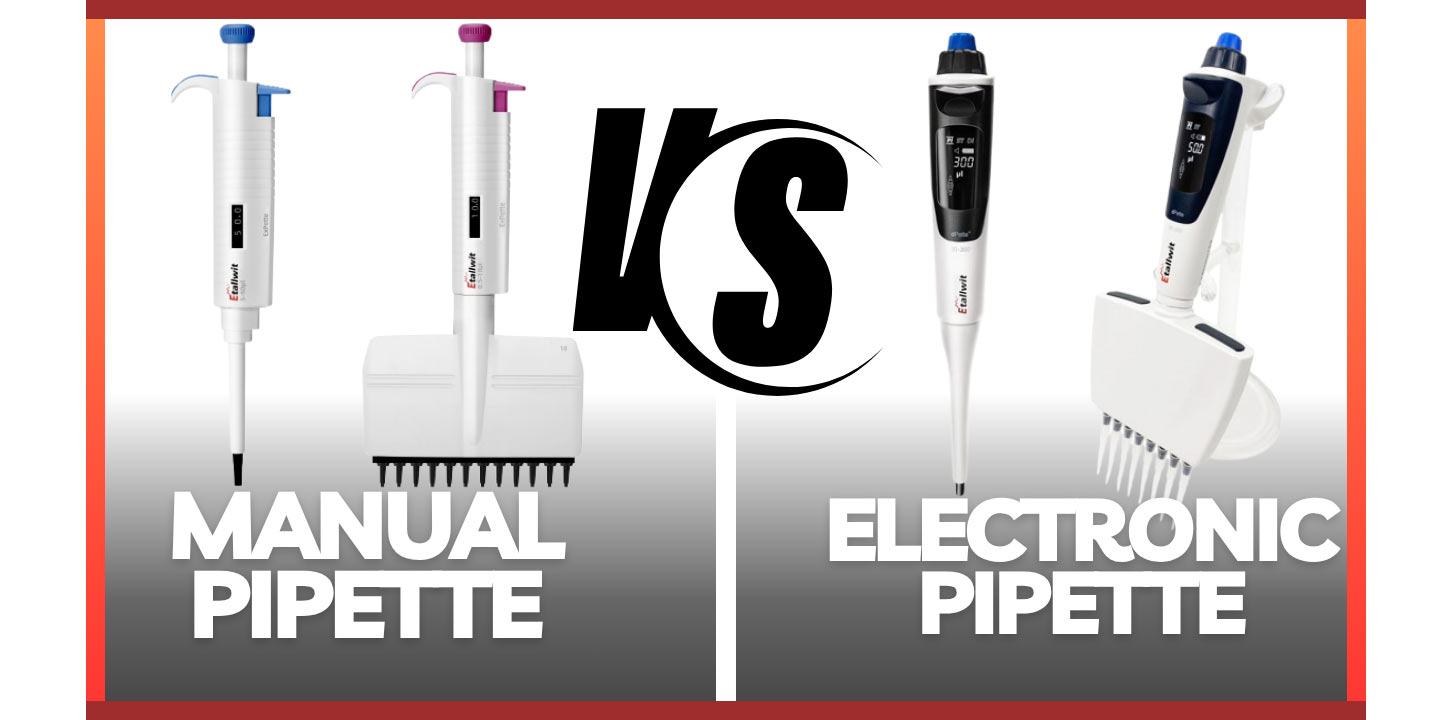

Manual vs. Electric Pipettes: Which One Fits Your Lab Best

Discover the core differences, advantages, and applications of manual and electric pipettes for efficient liquid handling.What Are Pipettes and Why Are They Essential in Laboratories?Pipettes are precision instruments widely used in molecular biology, chemical analysis, clinical diagnostics, and pharmaceutical R&D. They enable scientists to transfer small volumes of liquid accurately and reproducibly. Among the many types, manual pipettesand electric pipettesare the two most commonly used options.Understanding the Core Components of a PipetteWhether manual or electronic, a pipette generally includes:üA plunger buttonüVolume adjustment dialüTip ejectorüDigital display (for adjustable models)üDisposable tip coneEach of these parts contributes to the accurate dispensing of liquid volumes, which is vital for achieving consistent and trustworthy results.Pipettes are mainly composed of the following parts:Manual Pipettes: Affordable and FlexibleHow They WorkManual pipettes rely on manual operation by the user. By pressing the button, the piston is pushed to create a negative pressure, which draws a specific volume of liquid. Pressing the button again releases the liquid. The measurement depends on the precise graduations on the pipette barrel.AdvantagesFlexible Operation: Suitable for scenarios involving small sample volumes and infrequent operations.Lower Cost: Relatively low costs for equipment maintenance and procurement.Easy Adjustment: Diverse experimental needs can be met by using different volume tips.DisadvantagesHigh Operator Dependence: The precision of operation is significantly affected by the user's sense of touch, speed, and force.Lower Reproducibility: Prolonged operation may cause fatigue, which can affect the stability of the data.✅ Related resource: Precision and Comfort with ExPette Pipettes – Designed for Optimal PerformanceElectronic Pipettes: High Precision Meets High ThroughputHow They WorkElectric pipettes are driven by an internal motor. They control the aspiration and dispensing processes through preset programs to achieve precise and uniform liquid transfer. Their operation typically requires only simple button control or touchscreen operation.AdvantagesHigh Precision and Reproducibility: Reduces human error and enhances the stability and reliability of experimental results. High Degree of Automation: Suitable for large-scale, high-throughput experiments, such as drug screening and genetic testing. Convenient Operation: Using preset programs can simplify complex operational procedures and reduce labor intensity.DisadvantagesHigher Cost: The equipment and maintenance costs are higher than those of manual pipettes. Technical Dependence: Regular calibration and software updates are required, and users need to undergo certain training before use.✅ Explore our advanced EtPette Series Pipettes–Your Professional Lab CompanionChoosing the Right Pipette for Your WorkflowDepending on experimental needs and personal background, different laboratories may have varying preferences for pipettes. Here are some suggestions for reference:Application TypeRecommended PipetteLow volume, occasional useManual PipetteRoutine high-throughput assaysElectric PipetteBudget-sensitive labsManual PipetteGLP-compliant, high-precision needsElectric PipetteConsidering the actual skills of laboratory personnel and budget arrangements, choosing the right pipette can effectively improve experimental efficiency and data quality.Selecting the correct pipette improves lab efficiency, ergonomics, and data reliability.Maintenance and Calibration Best PracticesWhether it is a manual or electric pipette, regular maintenance and calibration are key to ensuring the accuracy of experimental data:üRegular cleaning: Prevents residual liquids from causing cross-contamination.üCalibration checks: It is recommended to periodically test with standard liquids to ensure accurate volume measurements.üTechnical training: Regular training for operators to master the correct usage methods and troubleshooting skills.Manual vs. Electric: Final VerdictBoth manual and electric pipettes have their roles depending on lab size, frequency of pipetting, and required accuracy.Etallwit offers a full range of manual and electric pipettes, including multichannel models and high-precision electronic pipetting stations to meet every lab’s needs.If you have more questions about the selection, usage tips, or maintenance of pipettes, feel free to leave a comment in the comment section or contact our professional customer service team directly. We will provide you with one-on-one consulting services to help you find the most suitable laboratory solution.Contact Etallwit Scientificfor product consultations, bulk orders, and technical support.

How One-Piece Cryogenic Racks Enhance Ultra-Low Temperature Storage Performance

Discover why seamless, stainless steel cryogenic racks are the smart choice for ULT sample security.The one-piece molding technology reduces the number of welding points or connection parts in the freezer rack, lowering the risk of corrosion caused by long-term low-temperature environmentsThis reduces the risk of structural loosening, deformation or damage. The overall structure is more stable and durable, capable of withstanding the weight of a large number of samples without deformation.Seamless Structure, Superior StrengthThese freezer racks are typically custom-designed based on the internal dimensions of ultra-low temperature (ULT) freezers, ensuring precise alignment with the interior shape and size of the refrigerator. This tailored approach maximizes storage space utilization and allows for increased frozen sample capacity.Maximized Storage EfficiencyThe monolithic cryogenic storage rack has a smooth and flat surface, with minimal gaps or edges, making it less likely to accumulate dust, frost, or harbor bacteria. This design facilitates easy cleaning and disinfection, which is beneficial for maintaining the purity and safety of the stored samples and reducing the risk of sample contamination.See our full range of Freezer Racksfor every lab layout.Hygienic and Easy to MaintainThe cryogenic storage rack is integrally formed, ensuring that the entire product has a consistent coefficient of thermal expansion and contraction. This effectively enhances the low-temperature tolerance of the rack, reducing the likelihood of issues such as brittleness and cracking that may occur in ultra-low-temperature environments. It ensures that the rack can still function properly at temperatures as low as -80℃ or even lower, maintaining good physical properties and mechanical strength.Why 304 Stainless Steel?The Etallwit monolithic cryogenic storage racks for ultra-low temperature freezers are entirely made of 304 stainless steel. This material has the following characteristics:· Corrosion Resistance:In ultra-low temperature environments, condensation or exposure to certain chemicals may occur inside the freezer. 304 stainless steel has excellent corrosion resistance, which can withstand the erosion of these factors and extend the service life of the storage rack.· High Strength:It possesses high strength and hardness, capable of supporting the weight of storage boxes and samples without deformation or damage. This ensures stability during frequent handling of samples.· Low-Temperature Adaptability:304 stainless steel maintains good toughness and strength even at low temperatures, preventing brittleness due to extreme cold. It is suitable for long-term use in the harsh conditions of ultra-low temperature freezers.· Ease of Cleaning:The smooth surface does not readily adhere to dirt and impurities, making it easy to clean and disinfect. This helps maintain the hygiene of the storage rack and prevents cross-contamination.Application ScenariosThe monolithic cryogenic storage racks for ultra-low temperature freezers are widely used in various places that require low-temperature preservation of biological samples, materials, or products, including but not limited to the following fields:Biomedical research: In scientific research laboratories, it is used to store cells, tissues, blood samples, biological macromolecules (such as DNA, RNA, proteins), etc., to provide sample support for disease diagnosis, drug development, basic biological research, etc.Clinical medicine: The hospital's laboratory, pathology department, reproductive medicine center and other departments are used to store patients' clinical samples, such as pathological sections, blood specimens, semen samples, etc., for subsequent testing, diagnosis and treatment reference.Biobank: Institutions dedicated to long-term storage of large numbers of biological samples, such as national biobanks, disease research sample banks, etc., one-piece molded cryopreservation racks help improve the density and management efficiency of sample storage and ensure the quality and safety of samples.Pharmaceutical industry: Pharmaceutical companies need to store various biological preparations, vaccines, drug intermediates and other samples during drug development and production. Ultra-low temperature refrigerator cryopreservation racks provide a stable low-temperature storage environment for these samples.Food industry:Used to store food microbiological samples, food additive samples, etc. for quality testing and research.Your Trusted Lab Storage PartnerAt Etallwit Scientific, we understand what matters in sample preservation: precision, reliability, and safety. Our cryogenic freezer racks are designed with input from scientists and engineers to meet the evolving needs of today’s labs.Contact us today to discuss your ULT freezer compatibility or explore bulk pricing options.Visit: www.etallwit.com| Email: service@etallwit.com

How Liquid Nitrogen Revolutionizes Ice Cream Making

In the 1990s, molecular gastronomy began to emerge. Pioneers such as Spanish chef Ferran Adrià and British chef Heston Blumenthal started to introduce scientific instruments into the kitchen. Chefs discovered that liquid nitrogen could achieve effects that traditional cooking could not: instant freezing (such as making "smoky ice cream"), altering the texture of food (such as directly solidifying liquids into a crispy outer layer), and creating dramatic visual effects (the white smoke produced during vaporization). Heston Blumenthal introduced liquid nitrogen ice cream at his restaurant, The Fat Duck, which became a signature dish. This innovation not only changed the way traditional cooking was done, but also laid the foundation for the application of liquid nitrogen in ice cream manufacturing.How Does Liquid Nitrogen Freezing Work?The unique texture and visual effects of liquid nitrogen ice cream are primarily due to its core principle:Ultra-low Temperature Flash Freezing: When liquid nitrogen comes into contact with the ice cream ingredients, it rapidly vaporizes and absorbs heat, freezing the mixture within seconds to tens of seconds. The resulting ice crystals are extremely small, avoiding the formation of large ice crystals that occur in traditional freezing processes. This results in a smoother and more delicate texture.Locking in Flavor and Nutrition: Rapid freezing minimizes water loss and oxidation, preserving the natural aroma and freshness of the ingredients (especially suitable for flavor-sensitive ingredients such as fruits and nuts).Why Liquid Nitrogen Ice Cream Is Smoother, Faster, and CleanerSmooth Texture without Ice Crystals: Ultra-rapid freezing forms microscopic ice crystals that are nearly imperceptible, delivering a silky-smooth mouthfeel.On-Demand Preparation:No pre-frozen equipment required, enabling fresh ice cream production directly at point-of-sale (ideal for restaurants and dessert shops).Healthier and Additive-Free:Rapid freezing reduces reliance on stabilizers and emulsifiers, supporting natural and clean-label formulations.Unlimited Creativity:Flexible recipe adjustments allow incorporation of alcohol, liquid ingredients (e.g., uncaramelized syrup), and other components challenging for traditional methods.Traditional vs. Liquid Nitrogen MethodsTo better understand the uniqueness of liquid nitrogen ice cream, we can compare it with traditional ice cream making:Comparison ItemLiquid Nitrogen Ice CreamLiquid Nitrogen Ice CreamFreezing TimeA few seconds to tens of secondsSeveral hours to a dayIce Crystal SizeMicron-level, no graininessLarger, may produce ice crystalsTextureLighter and smootherRelatively denseAdditive RequirementsCan be completely additive-freeOften requires stabilizers and emulsifiersEquipment CostHigher (requires liquid nitrogen tank, protective gear)Lower (conventional ice cream machine)Applicable ScenariosInstant making, high-end customizationMass production, regular salesWhere Is It Used? From Fine Dining to Science ShowsHigh-end Restaurants and Dessert Shops:Utilize the "smoke effect" of liquid nitrogen to attract customers and enhance the dining experience (e.g., molecular gastronomy restaurants).Customization Services:Adjust sweetness and ingredients on-site according to customer preferences to achieve personalized production.Events and Educational Demonstrations:Used in science popularization activities or interactive experiences for children to showcase the fascinating effects of low-temperature science.Safety Precautions When Using Liquid NitrogenPrevent Frostbite: Operators must wear heat-insulating gloves and goggles to avoid direct contact of liquid nitrogen with the skin.Ventilation: When liquid nitrogen vaporizes, it may displace oxygen. Operations should be conducted in well-ventilated areas to prevent the risk of suffocation.Container Selection:Use containers that are resistant to low temperatures (such as stainless steel) to avoid the risk of shattering in ordinary glass or plastic due to low-temperature brittleness.Liquid nitrogen tanksare not only a technological innovation in ice cream making, but also a key tool for enhancing product value and consumer experience. Looking ahead, with the growing demand of consumers for healthy food and unique experiences, liquid nitrogen ice cream is expected to find applications in more fields. From high-end catering to mass markets, from customized services to science popularization and education, liquid nitrogen ice cream represents not only a new culinary technique, but also the food industry's continuous pursuit of innovation and quality. As the technology becomes more widespread and costs decrease, liquid nitrogen ice cream may no longer be exclusive to high-end restaurants, but will enter the daily lives of more consumers, becoming an indispensable part of food culture.Why Etallwit Liquid Nitrogen Tanks Are Ideal?The unique charm of liquid nitrogen ice cream is inseparable from the precise support of high-quality liquid nitrogen tanks.As a professional supplier of liquid nitrogen tanks, Etallwit is committed to providing you with safe, efficient, and reliable solutions for the storage and transportation of liquid nitrogen.Whether you are a practitioner in the high-end catering industry or an innovator passionate about making liquid nitrogen ice cream, Etallwit liquid nitrogen tanks can meet your needs.Ready to bring innovation to your culinary or laboratory operations?Contact our teamfor tailored solutions and expert advice. Email: service@etallwit.com